I. Introduction

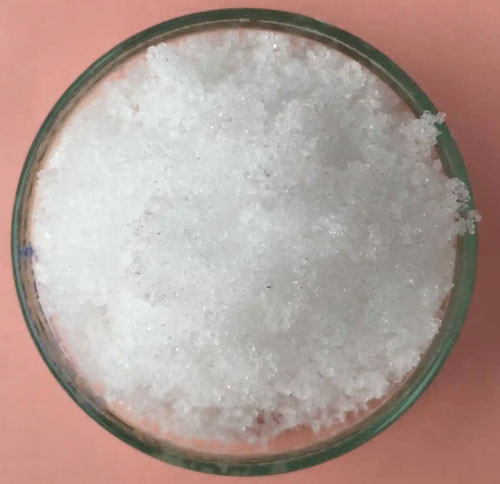

Disodium phosphate, also known as sodium hydrogen phosphate ( To know its specific description please read”what is disodium phosphate” ). It is a versatile compound that plays an important role in multiple industries, contributing to the quality and functionality of various products. Accordingly, the different applications lead to various reaction methods, and the raw materials to use are also different.

II.Reaction methods and Raw Materials for Disodium Phosphate

A.Neutralization reaction methods:

The main raw material for disodium phosphate is phosphoric acid. Depending on the process, another raw material is sodium hydroxide, sodium carbonate, or sodium bicarbonate

The reaction equation of these preparation methods are as follows:

Method 1:

H3PO4 + 2NaOH → Na2HPO4 + 2H2O

Method 2:

H3PO4+Na2CO3→Na2HPO4+H2O+CO2

Method 3:

H3PO4+NaHCO3→Na2HPO4+H2O+CO2

B. Spray drying methods:

The raw material is disodium hydrogen phosphate dodecahydrate(Na2HPO4·12H₂O).

Method 1:

This method is to add the raw material into the dissolving tank to heat and dissolve, add a small amount of industrial phosphoric acid, adjust the pH value, and atomize by sprayer. This process produces disodium hydrogen phosphate finished particle size of about 90μm accounted for 60%, the moisture content is less than 1%.

Method 2:

Dissolve disodium hydrogen phosphate dodecahydrate with pure water by stirring and heating, filter; add calcium chloride aqueous solution, after a series of steps, to get the finished product of anhydrous disodium hydrogen phosphate.

II. Conclusion

Disodium phosphate is a compound that has a significant impact on multiple industries, such as food, pharmaceuticals, and cosmetics. We usually apply different reaction methods as per the applications. So, the raw materials used are also different.